Higher than expected deformations may indicate that the structure is overloaded. At approximately 4:15 a.m. on January 17, 1978, the roof of the Hartford Civic Center Arena collapsed. Only six hours earlier, five thousand people had been in the arena watching a basketball game. The arena roof was a 90 by 110-meter space frame (Levy and Salvadori, 1992, Kaminetzky, 1991, Feld and Carper,1997).

During construction in 1972 and 1973, the inspection agency notified the engineers of excessive deflections (Levy and Salvadori, 1992). The measured deflection of the roof was twice that predicted by computer analysis. On the day of the collapse, the sum of dead and live loads was less than the design load.

The large deformations were a warning that the structure was not behaving as the computer model had predicted, and was on the verge of collapse (Levy and Salvadori, 1992). Kaminetzky (1991) suggests that the deformations were cries for help from the structure.

This case study can be introduced early in a mechanics of materials course when member deformations are first taught, and then discussed again when elastic buckling is encountered. Numerous factors contributed to the collapse, among them that the main top chords had a much lower buckling capacity than assumed in the original design analysis. The unbraced length of some compression members was 9.14 meters rather than the assumed 4.57 meters; thus, the capacity was reduced 75 % by this factor alone. Other factors reduced member capacity even further (Feld and Carper, 1997), and this case study could be revisited several times to bring out specific points about three-dimensional structural behavior, and the dangers of over-reliance on two-dimensional models.

What measures should be taken when observed structural deformations greatly exceed predicted deformations? Should a structure that will kill five thousand people if it collapses be designed with greater care and a higher factor of safety (Kaminetzky, 1991)

Rachel Martin’s Case Study – originally developed for the UAB REU Site, 1999

Hartford Civic Center Arena Roof Collapse

Hartford, Connecticut

January 18, 1978

By Rachel Martin

|

Design and Construction Collapse Causes of Failure Legal Repercussions Technical Concerns Procedural Concerns Ethical Concerns Bibliography |

Hartford CT, Civic Center Coliseum roof collapse, 1978 (Feld and Carper, 1997) |

Design and Construction

In 1970 Vincent Kling agreed to be the architect for the Hartford civic center. Shortly thereafter he hired Fraoli, Blum, and Yesselman, Engineers (F, B,&Y) to design the arena. In order to save money, F, B,&Y proposed an innovative design for the 300 by 360 ft. space frame roof over the arena. The proposed roof consisted of two main layers arranged in 30 by 30-ft grids composed of horizontal steel bars 21-ft apart. 30-ft diagonal bars connected the nodes of the upper and lower layers, and, in turn, were braced by a middle layer of horizontal bars. The 30-ft bars in the top layer were also braced at their midpoint by intermediate diagonal bars.

Space Frame Roof

Section of the Space Frame Roof

This design departed from standard space frame roof designing procedures in five ways.

- The configuration of the four steel angles did not provide good resistance to buckling. The cross-shaped built up section has a much smaller radius of gyration than either an I-section or a tube section.

|

|

|

- The top horizontal bars intersected at a different point than the diagonal bars rather than at the same point, making the roof especially susceptible to buckling.

- The top layer of this roof did not support the roofing panels; the short posts on the nodes of the top layer did. Not only were these posts meant to eliminate bending stresses on the top layer bars, but their varied heights also allowed for positive drainage.

- Four pylon legs positioned 45-ft inside of the edges of the roof supported it instead of boundary columns or walls (Levy and Salvadori, 1992).

- The space frame was not cambered. Computer analysis predicted a downward deflection of 13-in at the midpoint of the roof and an upward deflection on 6-in at the corners. These deflections were taken into account (ENR, Jan 26, 1978).

Because of these money-saving innovations, the engineers employed state of the art computer analysis to verify the safety of the building.

A year later construction began. To save time and money, the roof frame was completely assembled on the ground. While it was still on the ground the inspection agency notified the engineers that it had found excessive deflections in some of the nodes. Nothing was done. After the frame was completed, hydraulic jacks located on top of the four pylons slowly lifted it into position. Once the frame was in its final position but before the roof deck was installed, its deflection was measured to be twice that predicted by computer analysis, and the engineers were notified. They, however, expressed no concern and responded that such discrepancies between the actual and the theoretical should be expected (Levy and Salvadori,1992). When the subcontractor began fitting the steel frame supports for fascia panels on the outside of the truss he ran into great difficulties due to the excessive deflections of the frame. Upon notification of this problem, the general contractor “directed the subcontractor to deal with the problem or be responsible for delays.” As a result, the subcontractor coped some of the supports and prefabricated others in order to make the panels fit, and construction continued (ENR, April 6, 1978). The roof was completed on January 16, 1973 (Feld and Carper, 1997). The next year, a citizen expressed concern to the engineers concerning the large downward deflection he noticed in the arena roof, which he believed to be unsafe. The engineers and the contractor once again assured the city that everything was fine (Levy and Salvadori, 1992).

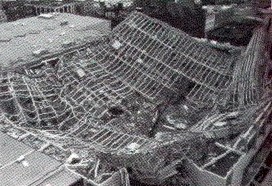

Collapse

On January 18, 1978, the Hartford Arena experienced the largest snowstorm of its five-year life. At 4:15 A.M. with a loud crack the center of the arena’s roof plummeted the 83-feet to the floor of the arena throwing the corners into the air. Just hours earlier the arena had been packed for a hockey game. Luckily it was empty by the time of the collapse, and no one was hurt (Ross, 1984).

Causes of Failure

Hartford appointed a three-member panel to manage the investigation of the collapse. This panel, in turn, hired Lev Zetlin Associates, Inc. (LZA) to ascertain the cause of the collapse and to propose a demolition procedure (Ross, 1984). LZA discovered that the roof began failing as soon as it was completed due to design deficiencies. A photograph taken during construction showed obvious bowing in two of the members in the top layer. Three major design errors coupled with the underestimation of the dead load by 20% (estimated frame weight = 18 psf, actual frame weight = 23 psf) allowed the weight of the accumulated snow to collapse the roof (ENR, April 6, 1978). The load on the day of the collapse was 66-73 psf, while the arena should have had a design capacity of at least 140 psf (ENR, June 22, 1978). The three design errors responsible for the collapse are listed below.

- The top layer’s exterior compression members on the east and the west faces were overloaded by 852%

- The top layer’s exterior compression members on the north and the south faces were overloaded by 213%.

- The top layer’s interior compression members in the east-west direction were overloaded by 72%.

In addition to these errors in the original design, LZA discovered that the details omitted the midpoint braces for the rods in the top layer. The exterior rods were only braced every 30-feet, rather than the 15-feet intervals specified, and the interior rods were only partially and insufficiently braced at their midpoints. This significantly reduced the load that the roof could safely carry. The table below compares some of the original details to actual designs used in the building, demonstrating the reduction in strength that these changes caused. Connection A was typically used on the east-west edges of the roof, while connection B was used on the north-south edges. Most of the interior bars used connection C, while a few used connection D. The key difference between the original and the as-built details is that the diagonal members were attached some distance below the horizontal members, and thus were unable to brace the horizontal members against buckling.

|

Connection A |

Connection B |

Connection C |

Connection D |

|

|

Original Design |

|

|

|

|

|

As-built Design |

|

|

|

|

Original vs. Actual Design

*Drawings by Rachel Martin based on information from ENR, April 6, 1978

he most overstressed members in the top layer buckled under the added weight of the snow, causing the other members to buckle. This changed the forces acting on the lower layer from tension to compression causing them to buckle also. Two major folds formed initiating the collapse (ENR, April 6, 1978). These were not the only errors that LZA discovered. Listed below are other factors which contributed to, but could not have caused, the collapse.

- The slenderness ratio of the built-up members violated the American Institute of Steel Construction (AISC) code provisions.

- The members with bolt holes exceeding 85% of the total area violated the AISC code (ENR, June 22, 1978).

- The spacer plates were placed too far apart in some of the four-angle members allowing individual angles to buckle.

- Some of the steel did not meet specifications.

- There were misplaced diagonal members (Feld and Carper, 1997).

Loomis and Loomis, Inc. also investigated the Hartford collapse. They agreed with LZA that gross design errors were responsible for the progressive collapse of the roof, beginning the day that it was completed. They, however, believed that the torsional buckling of the compression members, rather than the lateral buckling of top chords, instigated the collapse. Using computer analysis, Loomis and Loomis found that the top truss rods and the compression diagonals near the four support pylons were approaching their torsional buckling capacity the day before the collapse. An estimated 12 to 15 psf of live load would cause the roof to fail. The snow from the night before the collapse comprised a live load of 14 to 19 psf. Because torsional buckling is so uncommon, it is often an overlooked mode of failure (ENR, June 14, 1979).

Hannskarl Bandel, a structural consultant, completed an independent investigation of the collapse of architect’s insurance company. He blamed the collapse on a faulty weld connecting the scoreboard to the roof. This opinion conflicts with the opinions of all the other investigators (ENR, June 24, 1979).

Six years after the collapse, all of the parties reached an out-of-court settlement. While this was beneficial to the parties involved, it robbed the engineering world of the precedents that such a case could set. The issue of who ultimately holds responsibility for the structural integrity of a project when the tasks are divided among numerous subcontractors or if anyone does was never resolved (Feld and Carper, 1997).

The engineers for the Hartford Arena depended on computer analysis to assess the safety of their design. Computers, however, are only as good as their programmer and tend to offer engineers a false sense of security. The roof design was extremely susceptible to buckling which was a mode of failure not considered by in that particular computer analysis and, therefore, left undiscovered (Shepherd and Frost, 1995). A more conventional roof design would have been much stronger. Instead of the cruciform shape of the rods, a tube or I-bar configuration would have been much more stable and less vulnerable to bending and twisting. Also, if the horizontal and diagonal members intersected at the same place it would have reduced the bending stresses in these members. Finally, the failure of a few members would not have triggered such a catastrophic collapse if the structure had been designed and built with more redundancy (Levy and Salvadori, 1992).

The Hartford Arena contract was divided into five subcontracts coordinated by a construction manager. Not only did this fragmentation allow mistakes to slip through the cracks, but it also left confusion over who was responsible for the project as a whole. Even though the architect recommended that a qualified structural engineer be hired to oversee the construction, the construction manager refused saying that it was a waste of money and that he would inspect the project himself. After the collapse he disclaimed all responsibility on the grounds that a design error had caused the collapse. He believed that he was only responsible for ensuring that the design was constructed correctly and not the performance of the project. It is important for the responsibility for the integrity of the entire project to rest with one person. Fragmented responsibility leaves no one with a sense of or a real concern for how everything will work together making errors more likely to go undetected.

As a result of the construction manager’s refusal to hire a structural engineer for the purpose of inspection, no one realized the structural implications of the bowing structures. This collapse illustrates the importance of having a structural engineer, especially the designer, perform the field inspection. The designer understands the structure that is being built and would best be able to recognize the warning signs of bad design and rectify them before they grow to catastrophic proportions.

Finally, the Hartford department of licenses and inspection did not require the project peer review of the arena design, which it usually did for projects of this magnitude. If a second opinion had been required the design deficiencies responsible for the arena’s collapse probably would have been discovered. Peer reviews are an essential safety measure for all high capacity buildings and structures experimenting with new design techniques (Feld and Carper, 1997).

The excessive deflections apparent during construction were brought to the engineer’s attention multiple times. The engineer, confident in his design and the computer analysis which confirmed it, ignored these warnings and did not take the time to recheck its work. An ethical engineer would pay close attention to unexpected deformations and investigate their causes. They often indicate structural deficiencies and should be investigated and corrected immediately. Unexpected deformations provide a clear signal that the structural behavior is different from that anticipated by the designer. Also, this collapse raises the important question of whether the factor of safety should be increased for buildings with high occupancy. Should the impact of a possible failure be taken into account in determining the factor of safety (Kaminetzky, 1991)?

Bibliography

“Collapsed Roof Design Defended.” ENR, June 29,1978.

“Collapsed Space Truss Roof Had a Combination of Flaws.” ENR, June 22, 1978.

“Design Flaws Collapsed Steel Space Frame Roof.” ENR, April 6, 1978.

The Education Committee of the Technical Council on Forensic Engineering of the American Society of Civil Engineers [ASCE]. Shepherd, Robin and David Frost (Eds.). (1995). Failures in Civil Engineering: Structural, Foundation, and Geoenvironmental Case Studies. New York: The Society.

Feld, Jacob, and Carper, Kenneth, Construction Failure (1997), 2nd Ed., John Wiley & Sons, New York, N.Y.

“Hartford Collapse Blamed on Weld.” ENR, June 24, 1979.

Kaminetzky, Dov, Design and Construction Failures: Lessons from Forensic Investigations (1991). McGraw-Hill, New York, N.Y.

Levy, Matthys and Salvadori, Mario (1992), Why Buildings Fall Down: How Structures Fail. W. W. Norton, New York, NY.

“New Theory on Why Hartford Roof Fell.” ENR, June 14, 1979.

Petroski, Henry (1985), “From Slide Rule to Computer,” To Engineer Is Human. St. Martins Press, New York, NY.

Ross, S. et al. (1984), “Hartford Civic Center, 1978.” Construction Disasters. McGraw-Hill Book Co, New York, NY.

“Space Frame Roofs Collapse Following Heavy Snowfalls.” ENR, January 26, 1978.

Illustrations from Chapter 6 of the book Beyond Failure: Forensic Case Studies for Civil Engineers, Delatte, Norbert J., ASCE Press.