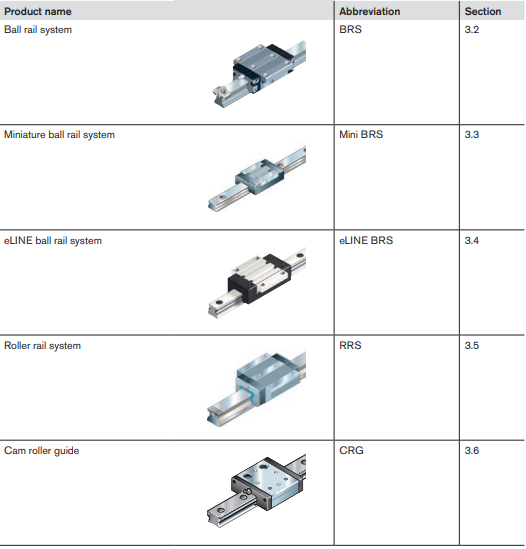

This section is broken up into the abbreviations of the different styles of profile rail systems, as well as dimension abbreviations to help classify specific body designs. This section also describes each component of a runner blocks and structural design. This page is extremely helpful when designing a product from the GoSelect tool.

Dimensions

- Ball Guide Block Sizing

- Width

- Flange (F)

- Slim (S)

- Wide (B)

- Compact (C)

- Length

- Normal (N)

- Long (L)

- Short (K)

- Extra Long (X)

- Height

- Standard (S)

- High (H)

- Low (N)

- Ball Guide Rail Sizing

- Width: Slimline (S) or Wide (B)

- Length: Normal (N)

- Height: Standard (S) or No base groove (O)

- Width

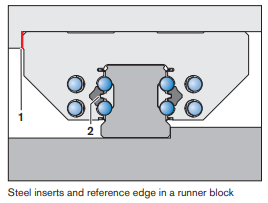

Runner block body- Depending on the version, the runner block body

can be made from heat-treated steel or anti-friction bearing steel. For special applications, especially for use in industrial robots, the body is made from aluminum. The aluminum version offers weight savings up to 60% compared to the steel version. Each runner block has a lateral reference edge (1). This edge mates with the adjoining structure. It permits precise alignment during installation and serves to transmit side loads.

Steel inserts- The runner blocks have two hardened steel inserts (2) made from anti-friction bearing steel. These inserts transmit the load from the runner block body to the balls.

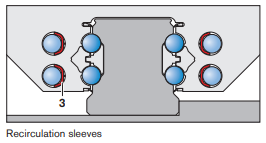

Recirculation sleeves- Each of the four ball return bores in the runner

block body is lined with a sleeve (3). This sleeve ensures good, low-friction recirculation of the balls inside the runner block. It also acts as a guide for the optional ball chain.

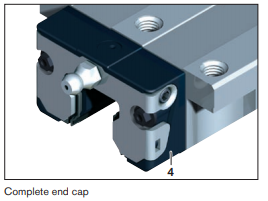

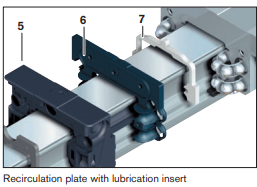

End cap- The end cap (4) consists of the recirculation plate (6), the lubrication insert (7), the ball guide (5), the sealing plate, and the threaded plate.

Recirculation plate- The recirculation plate (6) has specially designed lube ducts which conduct the lubricant directly to the lubrication insert, thus ensuring optimal lubrication results. It is thanks to this particular feature that long maintenance intervals or even

lubrication for life can be achieved. The recirculation plate also picks up and redirects the balls inside the runner blocks.

Lubrication insert- The lubrication insert (7) is made from openpored polyurethane foam. This foam soaks up the lubricant and releases it to the passing balls.The lubrication insert has been designed to allow lubrication with either oil or grease.

Ball guide- The ball guide is fixed in place by the recirculation plate. The balls are redirected in the space between these two parts. The ball guide also serves to retain the balls in the load-bearing raceway of the runner block when it is not mounted on the

rail.

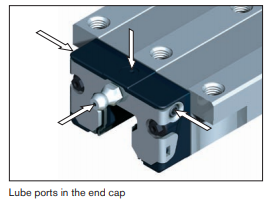

Lube ports- The ball guide also contains lube ports. The lube nipples or fittings of a central lubrication system can be inserted into these lube ports. The ports are located on the end face and at both sides. This allows lubrication from any of three directions without the need for an adapter. Lubrication from the top is also possible, by opening a predrilled hole. The hole can be punched open using a heated, pointed metal tool to allow lubrication through the machine table. An O-ring seals the interface to the machine table. High-profile runner blocks require an adapter to compensate for the height difference between the end cap and the runner block body.

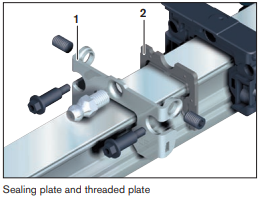

Threaded plate- The threaded plate (1) has two functions: it accommodates lube nipples and protects the end cap assembly. It is made from stainless steel.

Sealing plate- The sealing plate (2) on the end face protects internal runner block components from dirt particles, shavings and liquids. It also prevents the lubricant from being dragged out. Optimized sealing lip geometry results in minimal friction. Sealing plates are available with a standard seal, low-friction seal, or a reinforced seal.

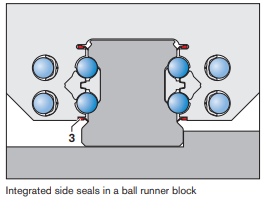

Side seals- Lateral sealing strips provide additional protection, keeping dirt and shavings out of the loadbearing zones. Each runner block has four of these side seals (3).

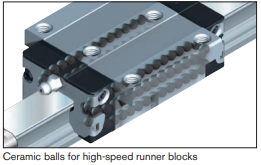

Balls- The rolling elements are balls. Normally, these are made from anti-friction bearing steel, grade 100Cr6. Stainless steel balls are used for runner blocks that will be operating in extremely hostile environments requiring corrosion-resistant elements. High-speed runner blocks have special ceramic balls. Because of their lightweight design, these balls deliver excellent dynamic performance. Ceramic balls are also good electrical insulators.

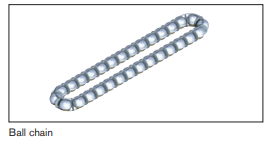

Ball chain- Runner blocks can also be equipped with a ball chain. The ball chain prevents the balls from bumping into each other and ensures smoother travel. This reduces the noise level. Runner blocks with ball chains have fewer load-bearing balls, which may result in lower load capacities.

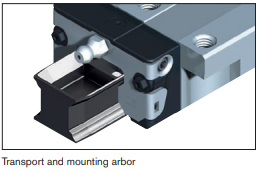

Transport and mounting arbor- Ball runner blocks are mounted on an arbor for

shipment. This arbor protects the balls from damage during transport and makes it easier to mount the runner block to and remove it from the guide rail.

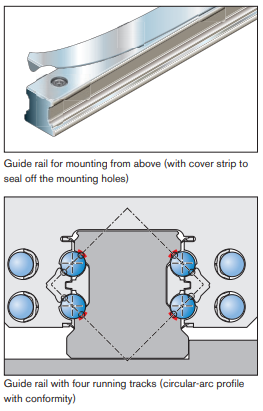

Guide rail- The guide rail is made from heat-treated steel. This steel was specially designed to meet linear motion requirements and therefore offers optimal system characteristics. The four ground running tracks have a circular-arc profile with conformity. This geometry ensures ideal running performance and can also compensate to a certain extent for misalignment. The running tracks are inductively hardened and precision-ground. Rexroth guide rails are also available in hard chrome plated (Resist CR) or in corrosion-resistant steel (Resist NR II) versions. These rails can be used in environments with aggressive media, such as dilute acids, alkalis or salt solutions. Depending on the size, one-piece rails can be delivered in lengths up to 6 m. If longer lengths are required, several rails can be fitted end to end to produce a composite rail. Guide rails can be bolted into place from above or below. V-guide rails are installed by pressing them into the mounting base.

Next: Sizes, Runner Blocks, and System Characteristics