Bosch Rexroth Bushing Selection

Selecting products can be challenging, but Bosch Rexroth has made it easy. Use the link HERE to use the Bosch Rexroth configurator tool. This tool is a streamlined approach to select the right product for your application.

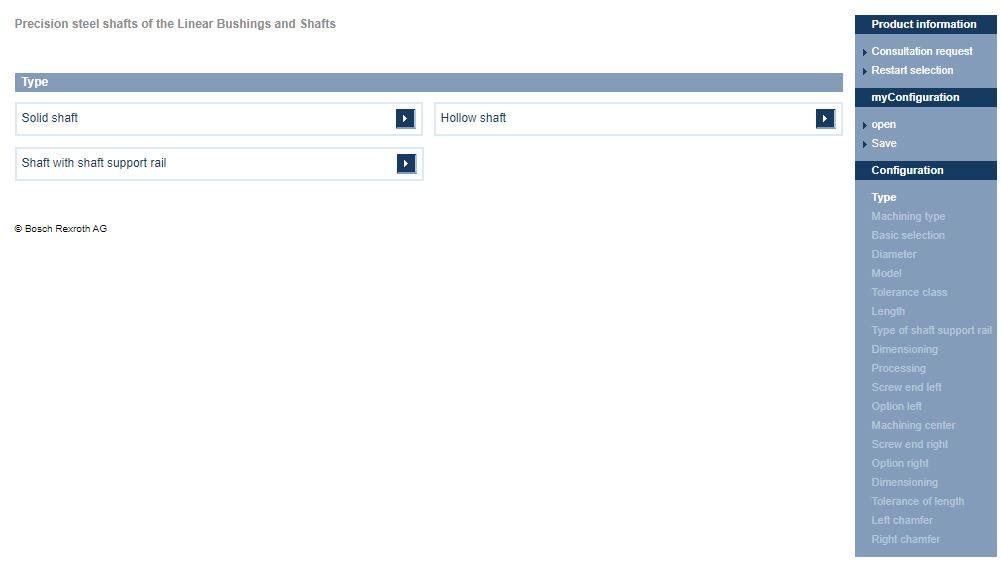

Following the configurator link will take you to this page:

Clicking on the configurator buttons allow you to properly design a working bushing assembly. At the end of the configurator process, a bill of materials will be generated with the bushing of your choice. Using this bill of materials, a quote can be generated by the Bosch Rexroth team.

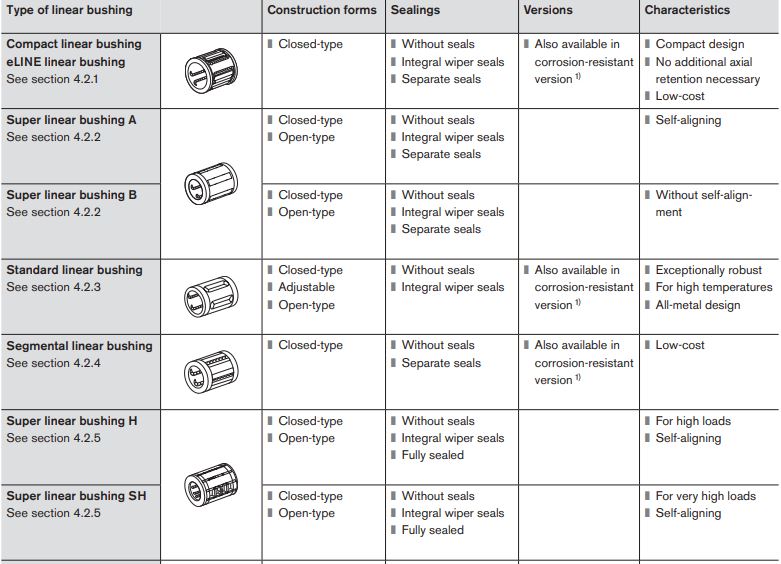

Here are some selection criteria that may be helpful for your project:

Deflection- When deflection must be avoided, high rigidity is required and shaft support rails and the appropriate open-type linear bushings are necessary. If deflection is less important, more economical closed-type linear bushings (possibly with shaft support blocks) can be used.

Vertical space requirement- The available construction height and the height

of the load carried will limit the size and the choice of linear bushing.

Direction of loading- If the direction of loading is different from the main direction of loading, the load capacities of the linear bushing will be reduced. The deviation

from the main direction has to be taken into account by applying a reduction factor in the design calculations.

Adjacent structure- It is generally best to use ready-to-install linear sets because they save time and money during design and installation. When installing linear bushings in customer-built housings, please follow the recommendations in the product catalog.

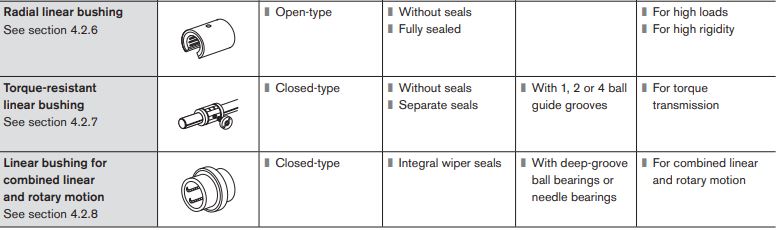

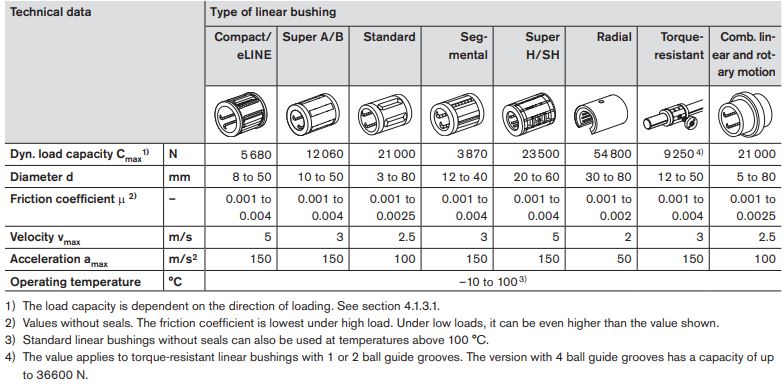

Travel speed- Not all types of linear bushings can be used when the velocity required is greater than 2 m/s.

Preventing rotary motion- If rotary motion must be prevented in linear bushing guideways with only one shaft, torque resistant linear bushings must be used.

Environmental conditions- Some types of linear bushings are better suited than others for particular environmental conditions because of their design. There are different sealing systems or corrosion-resistant versions to cater for different applications.

Initial selection- An initial selection of appropriate linear bushings can be made by analyzing these parameters. The tables in sections 4.1.1.5 and 4.1.2.2 also provide assistance in this pre-selection process. Normally, several types of linear bushings may be suitable for a particular application. If the type of linear bushing cannot be determined because of special conditions, you can always rely on Rexroth’s many years of experience. After selecting the type of linear bushing, the next step is to perform the design calculations.

Parallelism in the case of two shafts- High demands are placed on the accuracy of the spacing between two shafts and their respective linear bushings and on the parallelism of the shafts and the linear bushings. Inaccuracies lead to distortive stresses or overloading and therefore reduce the service life of the linear bushing guide. The Bosch Rexroth product catalog gives recommended values for the maximum difference in spacing, including parallelism offsets.

Operating temperatures- Linear bushings and shafts are essentially suitable

for a temperature range of –10 °C to +100 °C. For standard linear bushings with integral wiper seals and radial linear bushings with separate end seals, the maximum operating temperature is reduced to +80 °C (with brief peaks up to +100 °C). Higher temperatures are permitted for unsealed standard linear bushings. However, temperatures over +100°C result in a reduction in load capacity. At operating temperatures below freezing point, the formation of ice must be avoided.

Shaft deflection- In assemblies with rigid adjacent structures (housings, etc.) and longer distances between shaft support points, shaft deflection and the resultant pressure between the bushing edge and the shaft reduces the service life of self-supporting guides. The exceptions are Super Linear Bushings A, H and SH with inertial error compensation up to 0.5°. Please refer to the notes in section 4.1.4.7 when calculating shaft deflection.

Corrosion-resistant versions- Corrosion-resistant steels are steels to EN 10088.

In very critical, corrosive environments, the parts must be checked under operating conditions. Appropriate preserving oils and lubricants must be used.