Figure 1: Bosch Rexroth’s Smart Function Kit for Pressing

Image retrieved from https://www.boschrexroth.com/en/us/30-years-of-linear-axes/smart-mechatronix/smart-function-kit-pressing/

Introduction to the Smart Function Kit for Pressing

The Smart Function Kit for Pressing by Bosch Rexroth is a direct application of the technologies that were added to the Toolkit website by the BOSCH_TOOL2 Senior Design team (1,2,3,4,5). The SFK is a modular kit, containing mechanical, electrical, and software components to create an all-in-one mechatronic solution to a wide range of industrial applications. These applications fall into categories such as Assembly and Joining, Forming, and Testing. The SFK comes ready to use in a single package, with no programming knowledge required to make full use of the technology.

Here is a video introduction to the Bosch Rexroth Smart Function Kit for Pressing:

Applications of the Smart Function Kit for Pressing

The following pictures graphically describe some of the many industrial uses for the Smart Function Kit for Pressing:

Assembly and Joining

Forming

Testing

All graphics retrieved from https://www.boschrexroth.com/en/us/30-years-of-linear-axes/smart-mechatronix/smart-function-kit-pressing/

Components

The Smart Function Kit for Pressing consists of five main components: an Electromechanical Cylinder, a servo motor, a servo drive, an industrial PC, and custom Bosch Rexroth software.

Electromechanical Cylinder

The Electromechanical Cylinder (EMC) is a specialty high-performance alternative to traditional hydraulic and pneumatic cylinders developed by Bosch Rexroth. The EMC is a precision linear actuator whose main purpose is linear motion and can be applied in a wide range of applications. The EMC sizes available for the Smart Function Kit for Pressing ranges from the 40mm model up to the 100mm extra capacity option. For more information about Electromechanical Cylinders, please visit the dedicated pages on the Toolkit website here.

Servo Motor

Servo motors are self-contained electrical devices used as a control system to control the rotary motion or position of an object with high efficiency and precision. Servo motors combine the functionality of a regular motor with a sensor that collects information and provides feedback to correct or maintain its performance. The servo motor size included with the Smart Function Kit for Pressing automatically included depending on the overall size selected and comes with absolute value encoders and holding brakes. For more information about servo motors, please visit the dedicated pages on the Toolkit website here.

Servo Drive

A servo drive is the liaison between the industrial PC and the servo motor. The servo drive takes the information from the industrial PC running the system and converts it into voltage and current signals to feed the servo motor. The drive controller, and integrated control system as a whole, that comes with the Smart Function Kit for Pressing does not need configuration and is automatically configured based on the selected size of kit. For more information about servo drives in general, please visit the Bosch Rexroth product pages for servo drives here.

Industrial PC

Industrial PCs (IPCs) are PCs that are specialized for an industrial environment. They are normal computers, running an operating system like Windows, but built with components that are meant to withstand a harsh environment such as a factory floor. In the context of the Smart Function Kit for Pressing, it acts as the brains of the operation and is the motion and logic controller for the system. The Smart Function Kit for Pressing utilizes the Box PC PR21 from Bosch Rexroth. For more information about industrial PCs and Motion and Logic Control in general, please visit the dedicated pages on the Toolkit website here.

Software

The software included with the Smart Function Kit for Pressing is preinstalled onto the machine. The servo drive is capable of automatic parameterization to reduce time spent setting up the kit. The UI includes a modern and intuitive design with simplicity in mind. Conveniently, no programming knowledge is required to set up the kit, allowing technicians and engineers alike to get right into working with the machine.

Purchasing Information

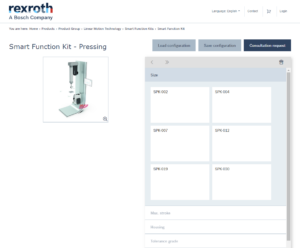

Figure 2: Smart Function Kit for Pressing Configurator

Image retrieved from https://www.boschrexroth.com/ics/ref/config?matno=R156699998&cat=Linear-Motion-Technology-Catalog&p=p929654&o=Desktop&_tunnel=1&language=en

The product selection and purchasing process for the Smart Function Kit is very straightforward. Bosch Rexroth offers two options: their LinSelect software tool, or their online configurator to select the components that make sense for your system. With the online configurator, you can customize the following about the Smart Function Kit for Pressing:

- Size – Determines maximum nominal force from 2kN to 30kN.

- Maximum stroke up to 400mm

- Servo motor mounting position – Colinear or parallel

- Motor cable length

- Servo drive type

Once the Smart Function Kit for Pressing is configured, the specific configuration can be added to the shopping cart or saved to be accessed later. It is suggested that the customer make a consultation request with a Bosch Rexroth representative, which is available on the Smart Function Kit for Pressing configurator.

Smart Function Kit for Pressing Webpage

If you would like to learn more about the Smart Function Kit for Pressing, please visit the Bosch Rexroth webpage here.