The Electromechanical Cylinder is a specialty electronic device developed by Bosch Rexroth. The EMC is a precision linear actuator whose main purpose is linear motion and can be applied in a wide range of applications.

Structural Design

The Electromechanical Cylinder is made up of a Ball Screw Assembly with a piston rod attached to the screw drive nut, with everything sealed inside of a metal housing. A servo motor or other driving mechanism is attached on the screw end of the Ball Screw Assembly to provide the torquing motion. As the screw shaft rotates, the drive nut from the Ball Screw Assembly moves up and down along the shaft, resulting in the linear motion of the piston rod extending and retracting. One particular configuration option of the EMC can add limit switches to the interior of the EMC, which can help prevent damage during operation.

For more information about what the Ball Screw Assembly is and what it does, please refer to the Ball Screw Assembly Toolkit pages here.

Advantages of the Electromechanical Cylinder

The Bosch Rexroth website advertises a multitude of advantages to using the Electromechanical Cylinder over other available options on the market:

- High performance and cost effectiveness from the Ball Screw Assembly technology

- Wide configuration options and modularity

- Low design and implementation costs for customers because the EMC comes preassembled

- Smart programmable drive system allows for complex travel profiles

- Lubrication options minimize maintenance

- IP65 protection and chemical resistant options available to increase hygiene

Applications of the Electromechanical Cylinder

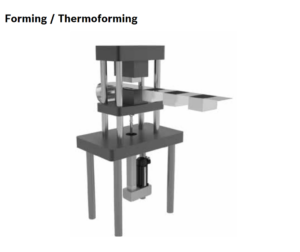

Electromechanical Cylinders are advantageous in many applications due to their size, accuracy, and programmability. The high configurability of the EMC can result in quite compact cylinders that can fit in tight spaces. Without providing an exhaustive list of applications, some examples from the EMC catalog include joining and pressing, transporting, forming, and lifting. Pictures of these applications are shown below:

Figure 1: Joining and pressing application of an EMC

Figure 2: Transporting application of an EMC

Figure 3: Forming application of an EMC

Figure 4: Lifting application of an EMC

All pictures retrieved from the EMC Product Catalog at https://www.boschrexroth.com/en/us/products/product-groups/linear-motion-technology/topics/linear-motion-systems/electromechanical-cylinder-emc/index