A Ball Screw Assembly (BSA) is a form of linear motion technology that converts rotational motion to linear motion. Ball Screw assemblies are used in machines that require a high degree of accuracy with their movements and high load applications.

Ball Screw

A ball screw is the stationary shaft that the ball nut is attached to. The screw can be operated by motors, gears, pulleys or via handwheel. A ball screw is made of steel and is manufactured by one of two methods. Rolled ball screws are the most widely produced, it’s achieved by pushing an unheated blank shaft through dies that form the screw with the necessary threads by a deformation process. Ground ball screws are manufactured by cutting away material to create the desired threads.

Rolled Ball Screw Notes: the threads are more durable because material is being compacted and not cut away, heat treatments for strengthening of the steel occur after rolling and they are more cost effective because of the quicker manufacturing process.

Ground Ball Screw Notes: heat treatment occurs before grinding the blank, cleaner finish on the threads which reduce friction between the screw and the bearings of the ball nut and they have more precise accuracy tolerances.

Both methods of ball screw machining come in a variety of lengths, diameters, load capabilities, tolerances and can be machined for left or right hand threads.

Screw ends are machining options for both ends of a ball screw to serve as a connection element for drive units or low friction support bearings. Bosch Rexroth has a wide selection of options available to facilitate most needs.

The following size configuration will be the necessary information to order a ball screw:

Nominal Screw Diameter

Lead

Ball Diameter

Example: 12 x 10R x 2 This size corresponds to a screw that has a 12mm diameter, a right hand thread that moves linearly by 10mm for every screw rotation and requires 2mm ball bearings in the nut.

Tolerance grades of the screw are T3, T5, T7 and T9. The different grades represent the maximum amount of deviation allowed with a travel distance of 300 millimeters.

T3- 12 micrometers T5- 23 micrometers

T7- 52 micrometers T9- 130 micrometers

The different series of ball screws manufactured by Bosch Rexroth are miniature series, standard series, speed series and high performance series.

Ball Nut

A ball nut acts as a carriage for the component that needs moved linearly as the ball screw is rotated. Ball bearings inside the ball nut contact the screw to provide a near frictionless contact surface. A ball return system picks up the ball bearings at the end of the ball nut and redirects them to the front to provide a recirculation path. Because the ball bearings are contained between the ball nut and the screw, it is important that the ball nut is not removed from the ball screw, they are shipped already installed.

Three forms of ball nuts are manufactured by Bosch Rexroth:

- A screw in ball nut has threads for applications where it can be directly coupled to a threaded structure without the need for nut housing. (The nut housing is a component that will attach to certain ball nuts to provide a surface to mount the component that will be moved.)

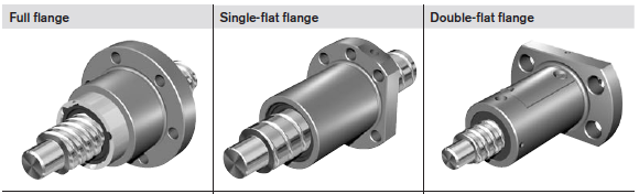

- Flanged ball nuts comes in different configurations such as a full flange, a single-flat flange and double-flat flange.

- A cylindrical ball nut is a cylindrical shape and uses a keyway to transfer the torque between itself and the nut housing.

The dimensions of the ball nut must match the dimensions of the ball screw that was chosen using the layout:

The dimensions of the ball nut must match the dimensions of the ball screw that was chosen using the layout: The addition of the (i) in this ordering code stands for the number of ball track turns that ball nut will have. The number of ball track turns is the number of full threads that will be occupied by the ball bearings inside the ball nut at any given time.