Accuracy classes define the tightness of the tolerances for the runner block. The more precise the system, the better manufacturing results. As precision increases, so does the cost per item.

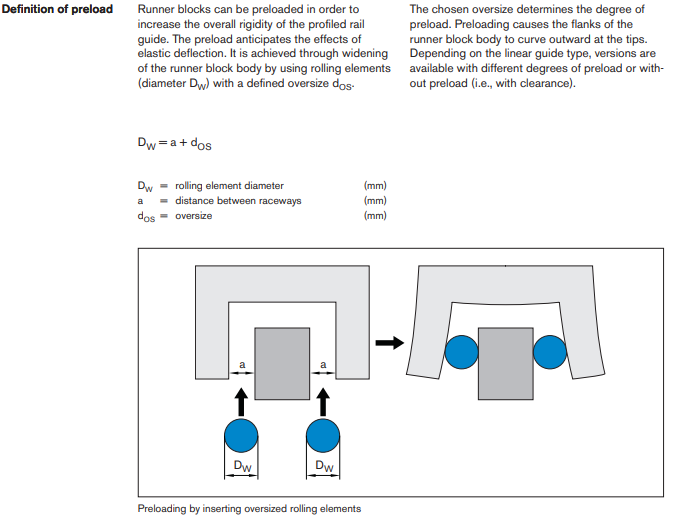

When rails and runner blocks are subjected to large loads, the material may have some minor deflection that may effect the systems performance. Preloading is the process of bending the runner block or rail in the opposite direction of load in order to fight the deflection.

Accuracy Classes

- Discuss the definition of the accuracy classes and the tolerances associated with the following:

- N- Normal (H = ±100 µm, A3= ±40 µm)

- H- High Precision (H = ±40 µm, A3= ±20 µm)

- P- Precise (H = ±20 µm, A3= ±10 µm)

- S- Super Precise (H = ±11 µm, A3= ±8 µm)

- U- Ultra Precise (H = ±10 µm, A3= ±7 µm)

- X- Extra Precise (H = ±5 µm, A3= ±5 µm)

- Describe Parallelism Offset Tolerance

Preload Classes

- C0

- No preload

- C1

- Moderate preload: Low loads, high demands on overall rigidity

- C2

- Average preload

- C3

- High preload