Introduction

Bearings are an important part of any mechanical system. Their use is so common that most people have at least heard the word before, even if they don’t know what a bearing looks like or how it functions. On this page, we will discuss the benefits of using bearings, as well as the different types of bearings and their applications.

Basic Theory

Definitions:

- Bearing Dynamic Capacity is defined as the constant stationary radial load which a rolling bearing can theoretically endure for a basic rating life of one million revolutions. Values for this important bearing parameter, C, are shown in each bearing table except Crane Hook bearings. Bearing dynamic capacity is used to predict a rating life for each bearing at its anticipated loading and rotational speed

- Bearing Static Capacity is the maximum load that can safely be applied to a non-rotating bearing that will not cause subsequent bearing operation to be impaired. It is based on calculated contact stress at the center of the most heavily loaded rolling element where it contacts the Inner Race

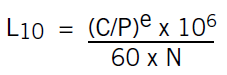

- Rating life is the bearing life calculated for 90% reliability. This is the amount of time that a group of apparently identical bearings will complete or exceed before the formation of a fatigue . The basic formula for calculating bearing rating life is:

where:

- C = Dynamic Capacity (dN or Lbs)

- P = Equivalent Bearing Load (N or Lbs)

- N = Rotating speed in RPM

- e = 3.0 for ball bearings, 10/3 for roller bearings

Applications/Examples

- Ball Bearings:

This type is most commonly used in projects. They can handle both radial and thrust loads. These bearings don’t carry much load on them to function properly.

- Roller Bearings

There are three types of roller bearings:

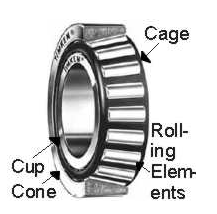

- Tapered Roller Bearings

These bearings are usually used in pairs so that symmetric axial load is supported on both sides.

These bearings are usually used in pairs so that symmetric axial load is supported on both sides.

They provide high accuracy, support all sorts of loads.

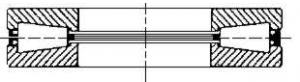

- Cylindrical Rollers

They have a high radial load capacity and are suitable for high speeds

- Needle Rollers

Have the ability to handle relatively high loads in a compact design envelope.

They are also the lightest and the smallest bearings.

Other advantages: have higher load capacity than single-row ball or roller bearings of comparable outside diameter; have the ability to handle a large more rigid shaft in a given application; have excellent rolling characteristics within a small cross section; have generally lower cost especially for the drawn-cup type compared with machined versions, also provide lower inertia forces that facilitate size and weight reduction.

Why Use Bearings

There are several benefits to using bearings in your designs. One of the most important uses is to reduce friction on rotating parts within the system. Reducing friction allows the entire system to run more efficiently by reducing the amount of power needed to spin parts.

For example, let’s look at a bicycle’s wheels. When you set a bike on its side and spin the wheel with your hand, the wheel seems to rotate with little effort and can keep spinning for much longer than you would expect. This is due to the ball bearings that the wheel is mounted on. Without them you would have to pedal much harder to reach the same speeds that you are accustomed to, i. e. you require more torque to overcome the extra friction on the shaft.

The reduced friction that the bearing provides can also increase the lifetime of the internal shaft, as the shaft is under less stress with the bearings in place.

What to consider when choosing a bearing

- Loads, Torques and Speed: magnitude and direction of forces, torques, and the speed of rotation will dictate what time of bearing will be suitable for the job. These criteria will also dictate if lubrication will be necessary to decrease friction and prolong the life of the bearing and contacting parts.

- Precision of the design: in many cases the precision of the design is crucial so environmental changes such as temperature, humidity, dust and vibration can alter the material.

- Bearing Noise: different bearings will have different operating noise, so if the design has to be quite special bearings need to be used, also lubrication needs to be used to make the bearings run smoother and quitter.

- Bearing Life: most bearing designs have certain life limits associated with the loads at which they operate. Bearing life needs to be considered in order to make the design more reliable or cheaper as needed.

The difference between a bearing and a bushing

They kind of have the same job. In fact, sometimes bushings are call “plain bearings”.

Bushings are good because they are very simple, cheap, provide damping as well as dust and chemical resistance.

Bushings are usually made of brass and bronze. These metals are quite soft and provide good gliding when in contact with shafts and the sleeve. Now bushings can be made from plastics, this makes them very cheap and very useful if some rotational movement is necessary in areas where chemicals are used or in food industry.

The great news is that we live in 21st century, and every day engineers and scientists come up with new ideas and inventions, so now we have bearings made from plastics. These bearings are quiet, chemical resistant, provide self-lubrication, and provide much less friction than the bushings. These bearings can come in special casings to make them dust resistant.

Self-aligning Bearings

Now this sounds great!

If you had a chance to build an assembly that had a shaft that needed to be supported on both ends, you probably know how precise the holes for the bearings or bushings need to be in order for the shaft to spin freely without excessive friction. These self-aligning bearings make manufacturing processes much much easier, because tolerances are not so tight anymore. Here are some of the advantages of self-aligning, lubrication-free bearings made from high-performance plastics:

- Cost effective

- Maintenance-free

- Lubrication-free

- Resistant to dirt and dust

- Corrosion resistant

- Can be used in liquid media

- Vibration dampening

- Inner race set in housings with very low clearance

- Dirt can become embedded for shaft protection

- 80% lighter than steel

Where to buy bearings

- https://www.bearingdistributors.com (if you want to support local distributors)

- https://www.astbearings.com (very detailed but may take a while and may be more expensive)

- https://www.motion.com/products/Bearings (user-friendly)

- www.ingus.com

References:

- https://spinnermint.com/guides/75/bearing-basics-parts-of-a-bearing-explained/

- http://training.bsc.com.au/Training/A9000/A9018/A9018-P01.htm

- https://www.littleblokefitness.com.au/difference-between-bushings-and-bearings-olympic-bars/

- http://www.skf.com/us/products/bearings-units-housings/engineered-products/polymer-ball-bearings/index.html