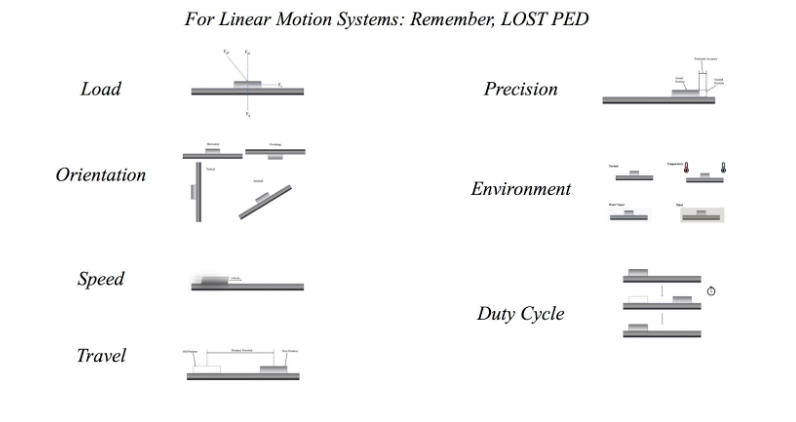

When deciding on a linear motion system, or any similar component, one should always keep in mind the acronym LOSTPED. The key features to look out for in reference to LOSTPED are the following:

L – Load:

Image created by BOSCH_TOOL

Most linear motion systems have a maximum load capacity that it can support without too much deformation. When looking for a linear motion system, one should look for one with a load capacity greater than the maximum load. In most situations, one should calculate a factor of safety for the linear motion system and choose a linear motion system with a factor of safety of between 2 to 6.

The linear modules are often not fully supported, but installed as unsupported structured. The system can be left unsupported or be supported at several points. In the unsupported configuration, the deflection must be taken into account in order to maintain the accuracy of the system. The Bosch manuals provide the user with charts in order that has the maximum load a system can handle before the frame deflects beyond a certain value.

Key Questions to Ask:

- What is the source of the load?

- Are there any special handling considerations to worry about?

- How much weight of force must be managed?

- Is the force a downward force? Lift-off force? Side force?

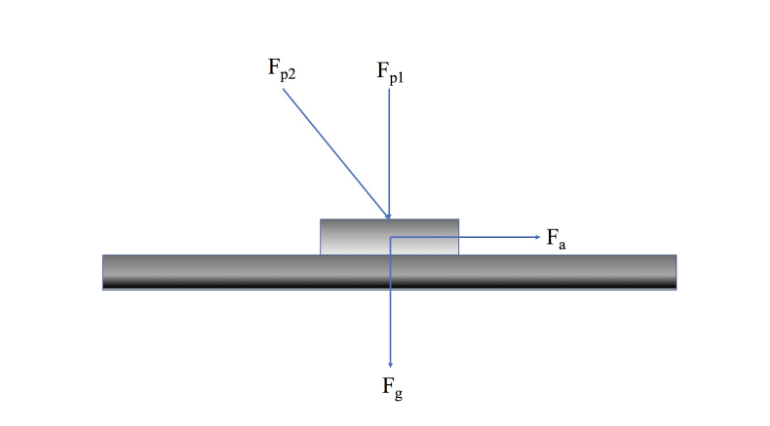

O – Orientation:

Image created by BOSCH_TOOL

The orientation of the forces in respect to the linear motion system is crucial to product selection as some linear motion systems have different load capacities dependent on the orientation of the load. Therefore, it is important that the linear motion system can be able to support the loads in the direction needed.

Key Questions to Ask:

- How is the linear module or actuator orientated?

- Is it horizontal, vertical, or upside down?

- Where is the load orientated relative to the linear module?

- Will the load cause a roll or pitch moment on the linear module?

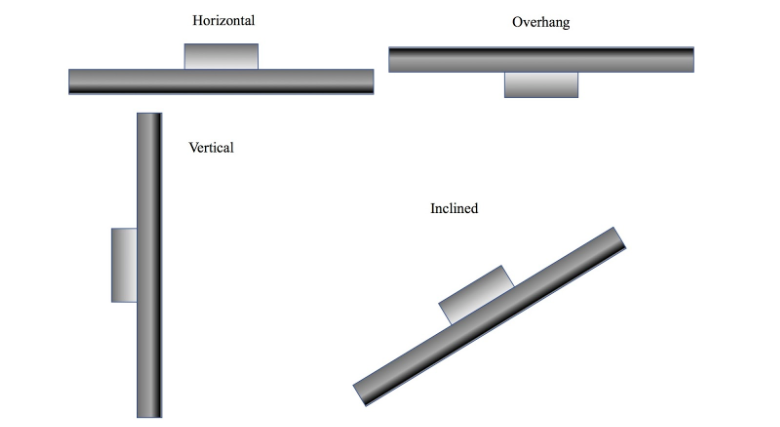

S – Speed (and Acceleration):

Image created by BOSCH_TOOL

The speed and acceleration of a linear motion system is important because it determines the types of linear drives that are able to be used. The speed and acceleration of a linear motion system also affects the calculation of life expectancy, as an applied load produces different forces during acceleration than it would at constant speed.

Key Questions to Ask:

- What speed or cycle time must be achieved?

- Is the linear module going at a constant speed or at a variable speed?

- How will a load impact acceleration and deceleration?

- What shape is the profile? A different shape profile handles acceleration and deceleration differently.

- Which linear drive will best address the speed and acceleration?

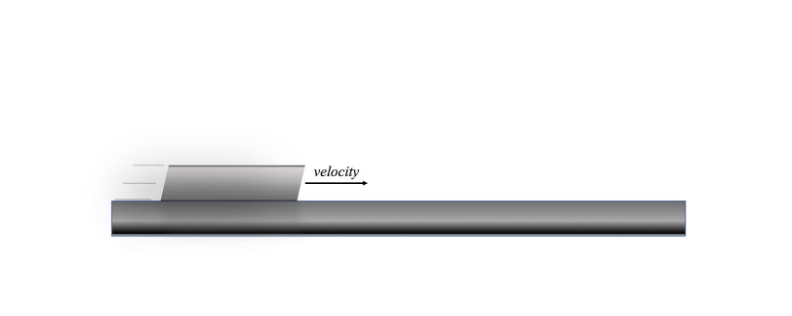

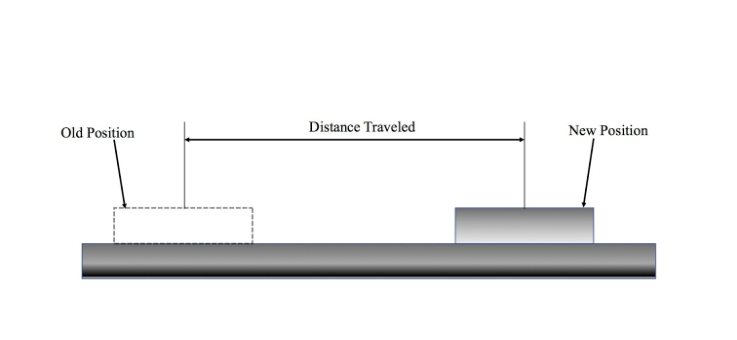

T – Travel:

Image created by BOSCH_TOOL

Travel is the range of motion that the linear motion system should be able to produce. The travel determines the length of the rail of the linear motion systems. For linear motion systems, be sure to account for some extra travel in case the linear motion system needs to make an emergency stop.

One important parameter to note when it comes to travel is the stroke length. The stroke length of the carriage defines the length of the linear module. The stroke length also helps to define the type of drive unit as the critical speed of the carriage becomes a factor beyond a certain length. In particular, if a long module is needed, then toothed belt drives are more preferable than ball screw assemblies.

Key Questions to Ask:

- What is the distance or range of motion?

- How much over travel may be required in an emergency stop?

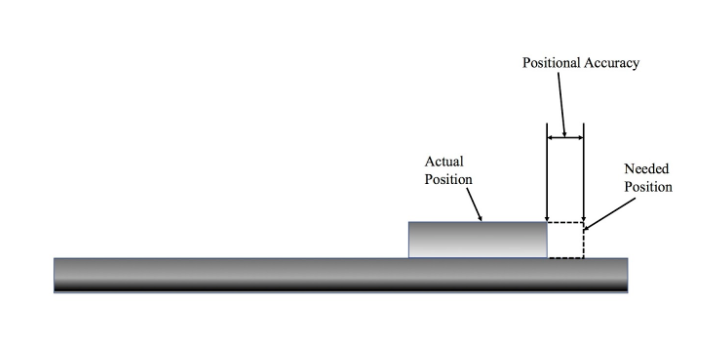

P – Precision/Accuracy:

Image created by BOSCH_TOOL

Precision for Bosch is a broad term that is used to refer to either:

-

- Travel Accuracy – How the system behaves when moving from point A to point B.

- Positioning Accuracy – How well does the system reach its target position.

- Repeatability – How well does the system move back to its starting position at the end of each stroke.

Precision is important because it determines the best drive-unit, as each type offers trade-offs between precision, speed and load capacity.

Key Questions to Ask:

- How important are travel accuracy, positioning accuracy and repeatability in the application

- Is precision more important than any of the other LOSTPED factors?

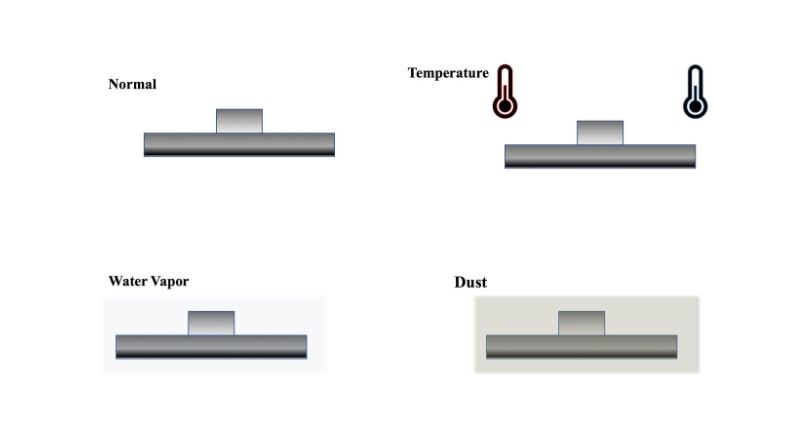

E- Environment:

Image created by BOSCH_TOOL

The surrounding conditions in which the system is expected to operate plays a big role in product selection. For instance, the temperature can affect the performance of plastic components and lubrication within the system. Dust, dirt, or debris is another significant factor as they can cause damage to the bearing raceways; therefore linear motion systems in those conditions will need a cover of some kind in order to protect the components.

Key Questions to Ask:

- What types of hazards or contaminants are present-extreme temperatures, dirt, dust, and liquids?

- Is the linear motion system a potential source for contaminants for the environment?

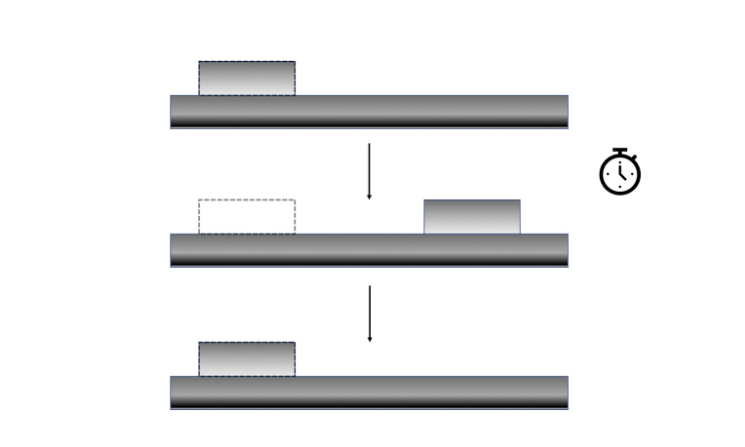

D – Duty Cycle:

Image created by BOSCH_TOOL

The duty cycle is the amount of time it takes to complete a cycle of operation. This directly affects the lifespan of the system as bearings will wear over many cycles. The duty cycle also covers the amount of in-use and rest times that the system will experience over its life. This is important to a system because the less the linear motion system is allowed to rest, the sooner that it will fail.

Key Questions to Ask:

- How often is the system in use, including any dwell time between strokes or moves?

- How long does the system need to last?

Choosing a Linear Motion System – Guideway

The guideway is one of the most important decisions in selecting a linear motion system, as the guideway needs to both support the weight of the load and move the load to the correct positions. The three types of guideways for linear motion systems are the ball rail system, the cam roller guide and the linear bushing

The ball rail system has higher rigidity and precision than the other two types and also comes standard with a preload. The maximum speed that it can travel is up to 5 m/s.

The cam roller guide has low noise levels and higher speeds, able to reach speeds of up to 10 m/s.

The linear bushings and shaft run smoother than the other two types. They are also not as sensitive to dirt or dust than the other two and are particularly robust.

Besides the type of guideway, the number of guideways also determine the system, as it can affect the overall rigidity of the system.

The number of guideways and carriages also effects the load capacities and moments of a linear motion system, as a system with more than one carriage has to be designed to carry the extra weight of the second carriage as well as any potential forces upon either carriage.

The life expectancy is also affected by the number of rails and carriages for a linear motion system, as more rails decrease the amount of load on each rail and thus increases the life expectancy for the module.

The accuracy of a two rail system is also more accurate than a one rail system because the spacing reduces errors due to yaw, pitch, and roll.

Resource: https://www.controldesign.com/

Which linear motion system is the best choice for my application?

There are many factors that go into deciding which linear motion system fits best for a particular job. If the linear motion system is going to be used for a lathing process, for example, then the positional accuracy and repeatability might be of the top priority. However if the linear motion system is to be used to move product from one location to another on an assembly line, then the speed and load capacity may be better deciding factors.

Which linear motion system is the fastest/strongest/most accurate/etc.?

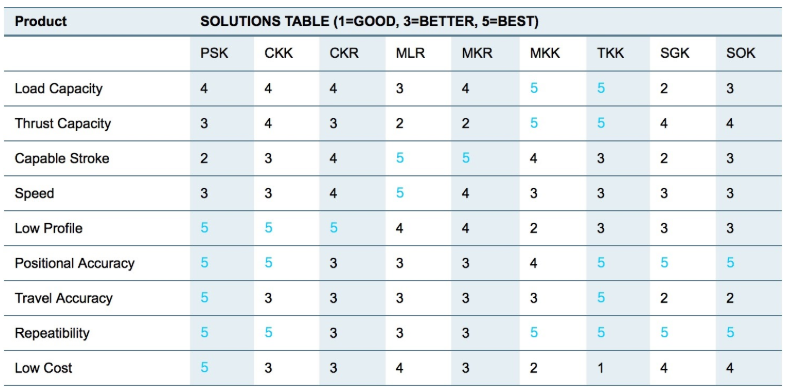

Below is a table from Bosch Rexroth showcasing some of the linear motion systems they used. This chart can be used as a gauge to determine the different situations where one type of linear motion system is better than another.

Resource: https://www.boschrexroth.com/en/us/products/.

Installation of Linear Motion System

Installation Space and Conditions

One of the most important factors in deciding what linear motion system to choose is the amount of space available for installation, as that directly affects the size of the system. If a longer system is needed, the available space for installation can also determine whether or not the system can be supported. This determines the type of system, as some types of system require support as they get longer.

Fastening Linear Motion Systems to the Mounting Base

When fastening the linear motion system to the mounting base, it is important not to fasten the mounting base to the end enclosures or end blocks as the frame is the main load-bearing structure.

The fastening options for linear motion systems include the following:

- Standardized Clamping Fixtures

- Sliding Blocks

- Connection Plates

- Brackets

- Threaded Anchor Strips

Each provides an easy method of connecting the linear mounting system to the mounting base.

Certain linear motion systems, such as the CKL, PSK, and TKK systems have a reference edge in order to help better align the system to the mounting base.

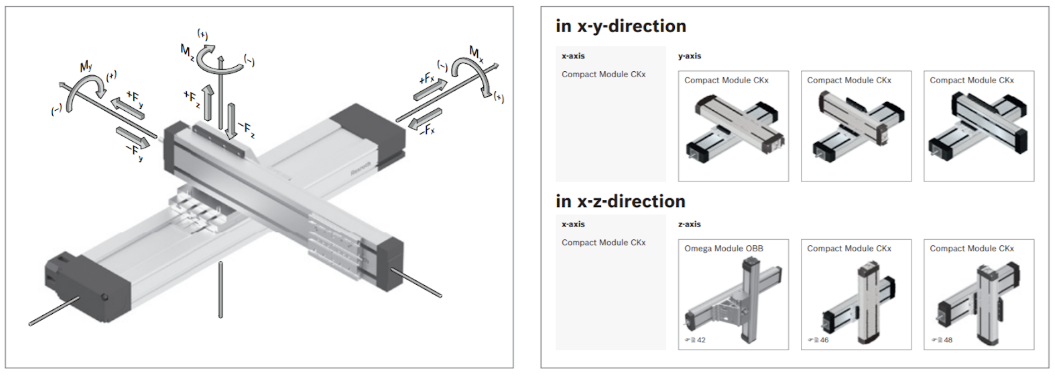

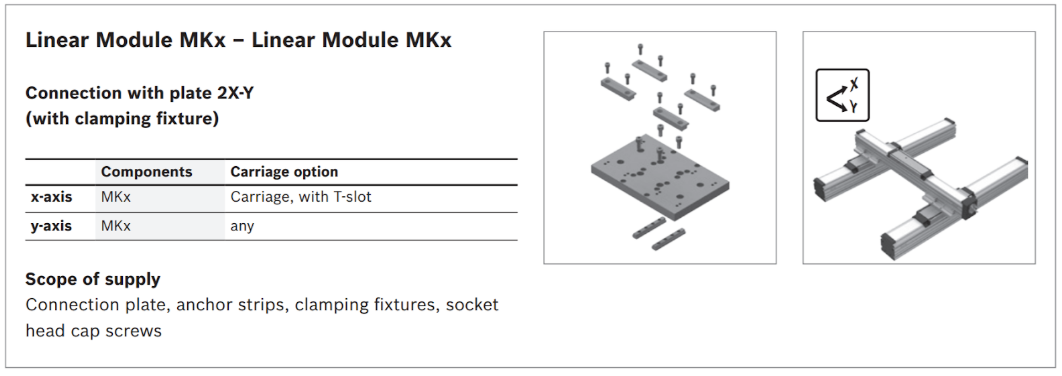

How to find the proper connection elements for linear motion systems

1. Determine the mounting orientation.

- Bosch Rexroth linear motion systems can be used in any orientation but defining this will be helpful in force calculations and selecting the right type of connection kit.

2. Define the linear motion systems to be used as the axes

- Different linear motion systems have different frame and slots so it is important to choose compatible modules

3. Combinations of linear motion systems

- When combining two linear motion systems, determine how the two will connect. One way to see how the two will connect is to download the CAD models for both of the systems and put them together in an assembly file. Having a visual representation of the connection points will help in determining which connection kit to choose.

4. Use Bosch Rexroth’s manual of connection technology for data values concerning each connection kit

https://store.boschrexroth.com/?cclcl=en_US

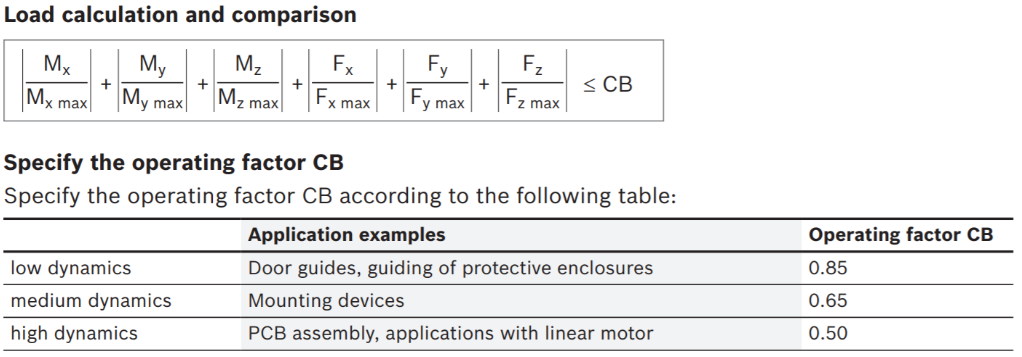

5. Determine the permissible load

- If a considerable load will be put on the linear motion systems, it is important to know if the connection kit can handle the load.

General Installation Notes

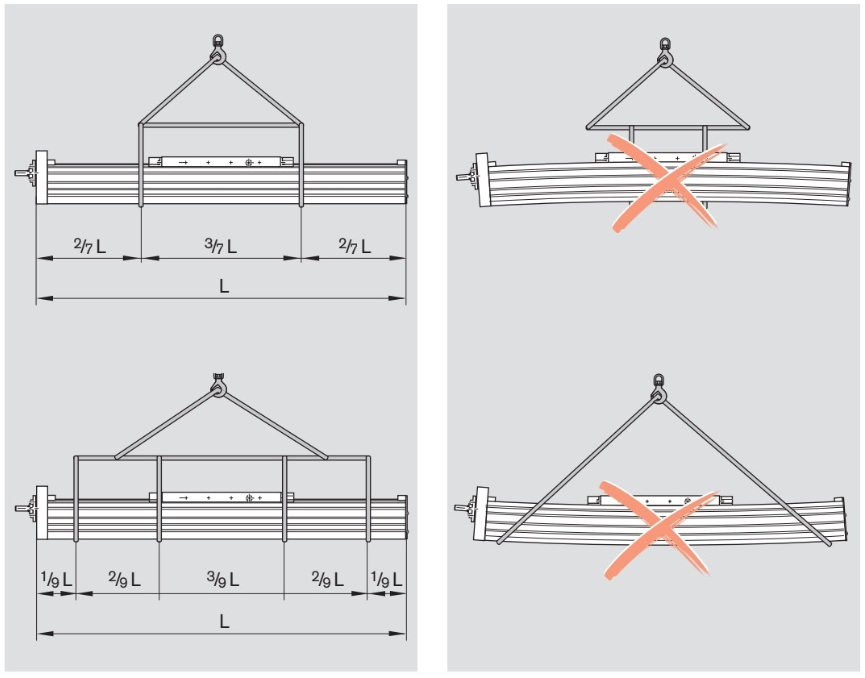

Some of the longer and heavier linear motion systems have a risk of deforming the guideway when lifting them. Therefore, it is crucial that the proper lifting equipment is used and arranged in such a manner to minimize the amount of deformation of the system. The following figure demonstrates some of the correct and incorrect methods for lifting such systems.

Resource: Bosch Rexroth Handbook (2007).

Care must be taken in order to make sure that the motor of the linear module will not interfere with other systems. It is therefore important to check for any interfering edges if the particular linear motion system has a motion.

In order to avoid the risk of buckling some linear motion systems, namely the ones with a ball screw drive, need to be installed in a certain way. For systems with ball screw drives, the screw’s fixed bearing must be orientated so it is at top if the system is going to be mounted vertically.

For linear motion systems with a linear motor, it is preferable to install them in a horizontal position. If the linear motion system needs to be installed vertically and the system contains a linear motion, then a braking device or a counterweight needs to be provided in order to prevent the carriage from dropping

It is preferable, whenever possible, to install the carriage with the axis rotated 180 degrees, so that the carriage is pointing downwards. This is to limit the amount of dust that may dirty the mechanical parts of the module.

Assembly Videos

This first video group of videos showcases how one can assemble a end block with different configurations

For end blocks with a flange and a gearbox:

https://www.youtube.com/watch?v=rPt3ddpn2N0&list=PLRO3LeFQeLyMF6evW4E7kR93JHzpJlV4r&index=6

For end blocks with a belt side drive

https://www.youtube.com/watch?v=pNznfqaMAf0&list=PLRO3LeFQeLyMF6evW4E7kR93JHzpJlV4r&index=7

For end blocks with a flange and coupling

https://www.youtube.com/watch?v=2e6FfX1rn4c&list=PLRO3LeFQeLyMF6evW4E7kR93JHzpJlV4r&index=8

Installation Mounting timing side belt drive

https://www.youtube.com/watch?v=fiBWN_jx_oU&list=PLRO3LeFQeLyMF6evW4E7kR93JHzpJlV4r&index=30