Types of Profiled Rail Systems:

Profile rails are essential gliding mechanisms used to aid movement of mechanical and assembly components. Think of profile rails as a very low friction and precise roller skate that is used to help carry loads of a system. The tops of the carriage (the “skate”) are versatile enough to have almost anything mounted on them! Consideration for the moments and placement of loads on the carriage increase the life expectancy, but these systems life-spans are essentially limitless if designed carefully. Profile rails operate by having groups of ball bearings, cylindrical rollers, and cam rollers that assists the movement of the carriage. You can read more about these style of rollers below!

It is critical to understand the different types of Profiled Rail Systems and understand when to use each one. Below are the three most common Profile Rail Systems. Ball Rail Systems consist of a runner block with four rows of steel balls that allow for high load capacities, speed, rigidity, and smooth performance. Ball Rail Systems are useful as they can be used for a variety of applications due to their ease of customization. Roller Rail Systems are similar to the Ball Rail Systems by design, but the Roller Rails use cylindrical steel rollers that allow for high load capacities since there is more contact area between the rollers and the guide rail. This application is used over Ball Rails when higher loads are expected, or high static torque is required. Roller Rails operate at a slower speed than the Ball Rails but makes up for it with higher load carrying abilities. Cam Rollers are quite different than the Roller Rails and Balls Rails as the rolling elements do not circulate between the runner blocks and the guide rails. Cam Rollers do not have accuracy classes like the previous two rail systems but are still very useful in the automation industry. Cam Rollers withstand high load and moment capacities, are very low weight, compact, rigid, and operate at the same speeds at Ball Rail Systems. For more detailed information and pictures, click on the links provided below!

Structural Design of a Rail System

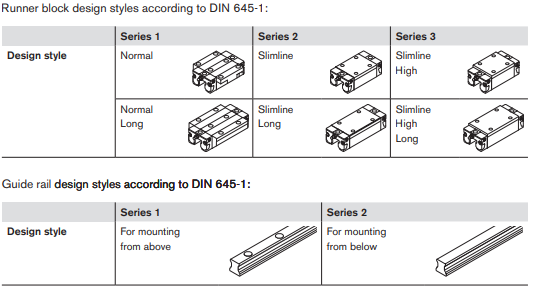

A profile rail system consists of two main parts, the runner block and a guide rail. Profiled rail guides are available in a wide variety of designs for use as machine elements. The main design styles and sizes are covered by the DIN 645 standard, which also specifies the main outside dimensions and the connection dimensions.

Profiled Rail Systems Accuracy/Preload Classes

Discusses the definition of the accuracy classes and the tolerances for profile rail systems

Profile Rail Example Calculations

Click here for additional calculations on the life expectancy of a profile rail system.

General Calculations for Runner Blocks

- Lifetime

- Constant Stroke Rate

- Variable Stroke Rate

- Load Capacity

- Calculated of Combined Load and Effective combined load.

- Safety Factor

- Max Speed/Acceleration

- Stress on the profiled rail system

- Rigidity (Demonstrate graphs of deflection vs. loading)

- Most of the graphs for the different lengths vs. deflection are approximated by linear functions

A Profile Rail Application: Integrated Measurement Systems

- Difference between absolute and incremental measurement systems.

- Describe benefits of using an inductive measurement system.

- The measurement device

- Voltage needed

- Resolution for different types of IMS.

Here is a short video on Integrated Measuring Systems (IMS-A)